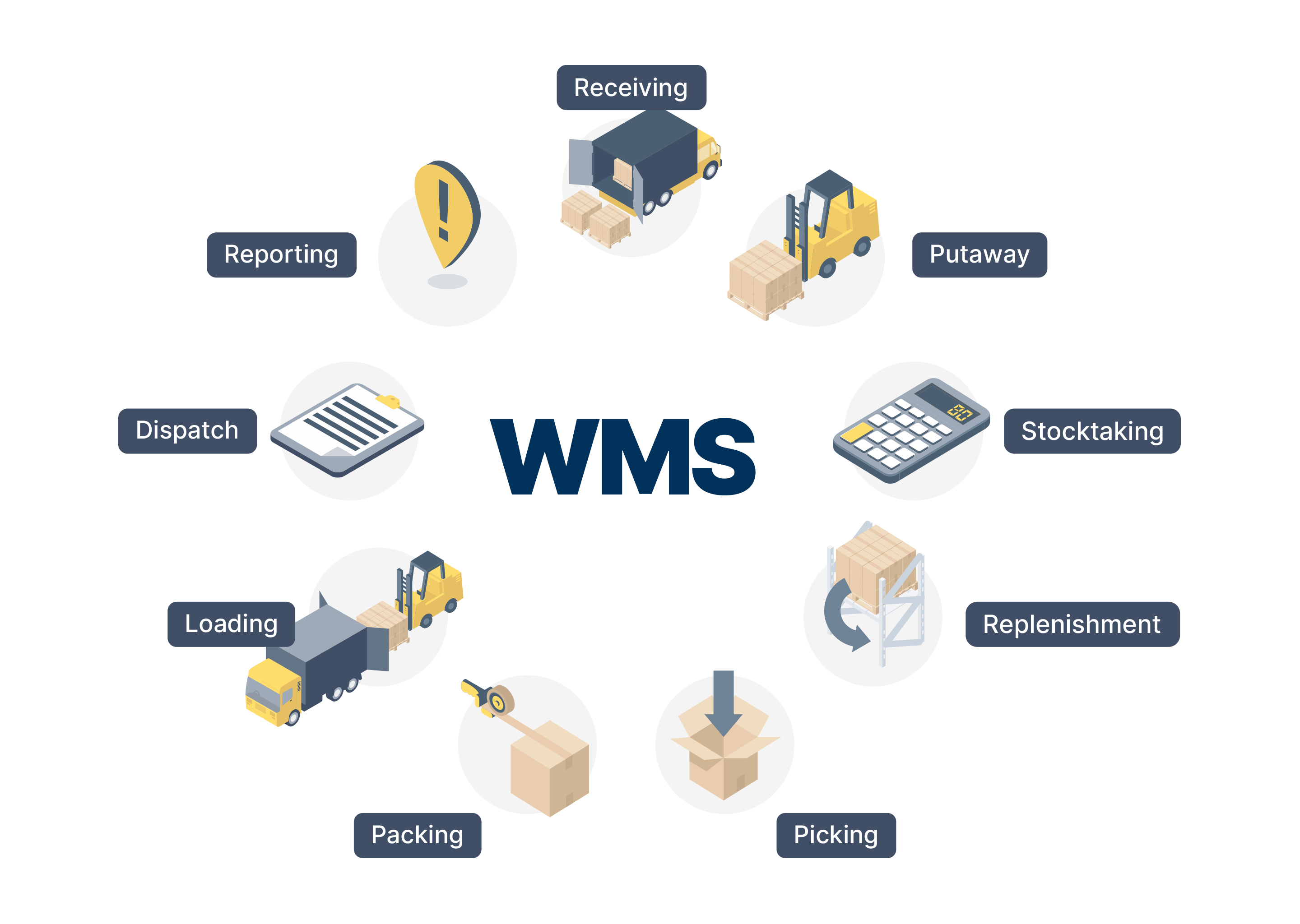

In today’s fast-paced market, maintaining operational efficiency is essential for success. A Warehouse Management System (WMS) is vital, acting as the central framework for streamlining warehouse operations. As a robust tool, it enhances productivity and reduces costs, empowering businesses to quickly adapt to changing market demands. By automating essential warehousing functions and organizing complex logistics, a wms simplifies intricate processes into manageable activities. This ensures that warehouse operations remain both agile and cost-effective, facilitating a smoother flow of goods and more reliable service delivery, ultimately contributing to improved business performance.

Let us delve into the key advantages of a warehouse management system.

Improved inventory accuracy

A well-implemented Warehouse Management System (WMS) greatly boosts inventory precision. Utilizing advanced tracking technologies like RFID and barcode scanning, a WMS minimizes human errors, ensuring that system records accurately reflect real-time stock levels. This high level of accuracy is crucial for reducing excess inventory costs, preventing stockouts, and supporting efficient just-in-time inventory practices, which in turn optimize operational efficiency and cost-effectiveness.

Enhanced labor management

Labor costs are a significant expense in warehouse operations. A Warehouse Management System (WMS) enhances efficiency by systematically organizing tasks and minimizing the time workers spend on each activity. This system allows managers to closely monitor workforce performance and strategically allocate staff to areas where they are most needed, thereby boosting productivity and reducing overall labor costs. This optimization is essential for maintaining cost-effective operations.

Faster order processing

Speed is paramount in warehouse operations to ensure customer satisfaction through quick deliveries. A Warehouse Management System (WMS) accelerates order processing by automating steps like order entry, picking, packing, and shipping. This not only quickens the overall workflow but also cuts down on errors, ensuring timely delivery of orders. Such efficiency significantly enhances customer satisfaction by reliably meeting delivery expectations.

Space optimization

Efficient use of space is another benefit of a well-chosen WMS. These systems help in organizing the storage of goods in a way that maximizes the use of available space. By analyzing the dimensions and weight of items, a WMS can suggest the best placement strategies, such as floor storage, pallet racking, or shelving, which not only helps in maximizing space but also in reducing damage and improving accessibility.

Enhanced reporting and analytics

Data is crucial for effective business management. A Warehouse Management System (WMS) offers comprehensive reports and analytics that enable managers to make well-informed decisions. These reports detail inventory levels, order fulfillment rates, and worker productivity. Armed with this data, businesses can spot trends, forecast future requirements, and fine-tune their operations to enhance both efficiency and profitability, ensuring they stay competitive and responsive in the market.

To sum up

Selecting the right Warehouse Management System can transform a chaotic warehouse into a smooth-running operation. It not only simplifies management tasks but also supports strategic planning and execution in the warehouse environment. By improving accuracy, enhancing labor management, speeding up operations, optimizing space, and providing valuable data analytics, a WMS becomes an indispensable tool for any business looking to thrive in the competitive market of today.